The use of pigment powder for epoxy projects has gained popularity in recent years. According to recent industry reports, the demand for creative epoxy applications has increased by 45% since 2021. This trend highlights a growing interest in custom aesthetics in various markets, such as art, home decor, and crafts.

Pigment powder for epoxy offers a broad spectrum of colors and finishes. Its versatility allows creators to tailor their projects uniquely. However, achieving the desired effect can be challenging. Mixing ratios, application methods, and curing times aren't always straightforward. Many users find themselves struggling with unexpected results. Sometimes, the colors don't appear as vibrant as intended. It's essential to experiment and adapt techniques to overcome these common hurdles.

Understanding the intricacies of pigment powder for epoxy can lead to stunning outcomes. Reports indicate that 70% of amateur creators express frustration with color matching. This feeling highlights the importance of proper knowledge and practice. Embracing the learning curve can transform the creative process. With patience and experimentation, artists can harness the full potential of their epoxy projects.

Pigment powder is a versatile additive for epoxy projects. It enhances color, texture, and artistic expression. According to a recent industry report, using pigment powder can increase project appeal by up to 35%. This statistic illustrates the potential impact on aesthetics.

The benefits of pigment powder extend beyond visual enhancements. It can improve the overall strength of epoxy mixtures. Research indicates that certain pigment powders can positively affect the hardness and durability of cured epoxy. This is crucial for both aesthetic and functional applications. However, finding the right balance is essential. Overuse can lead to clumping or uneven coloring.

Experimentation is key when working with pigment powders. Different brands and formulations react uniquely with epoxy. Some may require specific mixing methods to achieve optimal results. It's vital to test small batches first. Not every color translates perfectly in a cured state. Keep records of your mixtures to refine future projects. Embracing imperfections can lead to surprising outcomes, enriching the creative process.

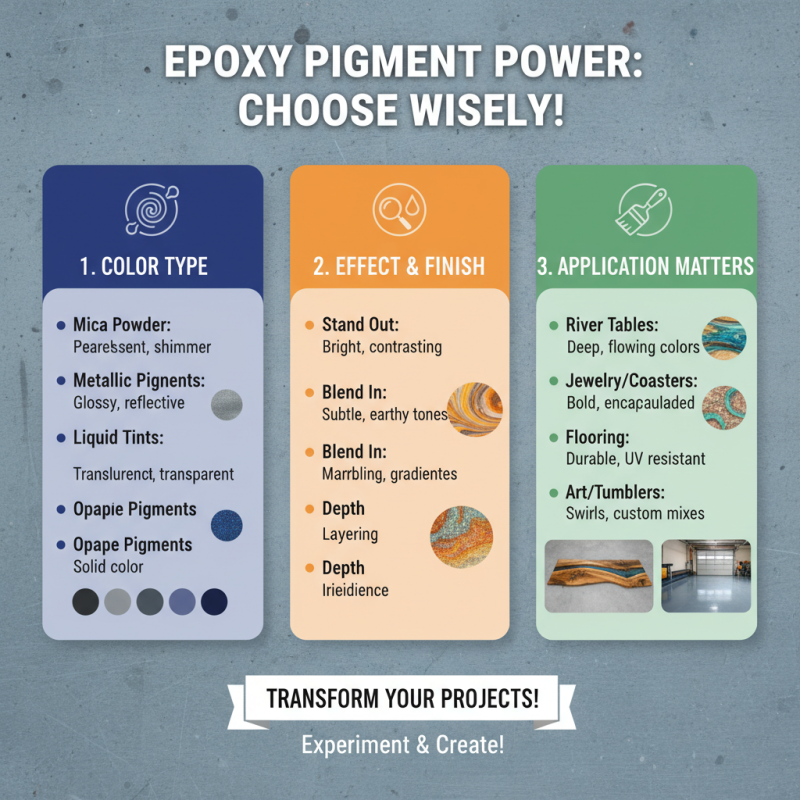

Choosing the right pigment powder for your epoxy application can be challenging. You want a color that stands out but also blends well. The choice can dramatically change the epoxy's final appearance.

Start by considering the type of project. For a more vibrant finish, opt for highly pigmented powders. These provide rich colors that catch the eye. Less pigmented options can give a soft, subtle look. Both choices have their strengths and weaknesses. A misstep in selection might lead to an undesired outcome.

Next, think about the mixing process. Some powders dissolve easily, while others might need more effort. The way they behave in epoxy can be unpredictable. Testing small batches can help you understand this better. You might find that a hue looks different in the mixture than in the final coat. It’s crucial to reflect on these inconsistencies to refine your approach.

Preparing epoxy resin for mixing with pigment powder is an essential step in achieving vibrant colors. Start by gathering your materials. You'll need clear epoxy resin, hardener, and your chosen pigment powder. Work in a well-ventilated and clean area. This will make the process smoother and safer.

Before mixing, measure the resin and hardener carefully. Often, a 1:1 ratio works well. Pour each component into a mixing cup. Stir slowly to reduce bubbles. It can be tempting to rush, but patience is key. Allow it to settle briefly. During this time, consider the amount of pigment you want. Too little results in dull colors, while too much can affect the resin's consistency.

Once your epoxy is ready, add the pigment powder. Mix gently, ensuring even distribution. Watch for clumps; they can ruin the appearance. You might need to adjust your pigment ratio based on the home lighting. It's a common mistake to overlook this aspect, leading to unexpected results. Keep an open mind; every project offers a learning opportunity.

Mixing pigment powder into epoxy requires careful attention. Ensuring even color is crucial for aesthetics and durability. According to industry reports, achieving uniform colors can vary based on the type of powder used. Some powders can clump more easily. This can lead to uneven mixing. Aim for a smooth paste before adding to your epoxy mixture.

When combining pigment powder, start small. Mix a few teaspoons with a small amount of epoxy. Use a stir stick or a mixing paddle. Scrape the sides to catch all powder. Gradually add more epoxy while mixing. This helps in controlling the color intensity. Keep in mind that certain pigments are more translucent. You might need more to achieve full opacity.

Pay attention to ratios. A study by resin experts indicates that an optimal mix ratio is around 10% pigment to 90% epoxy. However, proper experimentation is key. Each color behaves differently. You may find that some colors require adjustments. Keep notes of your ratios for future projects. It is essential to learn from each attempt, ensuring better results next time.

Applying pigmented epoxy can transform your projects dramatically. The right techniques can enhance color vibrancy and depth. According to industry data, over 70% of epoxy users report that colored epoxy boosts overall project appeal. To achieve the best results, consider the following tips.

Mixing the pigment thoroughly is crucial. Inconsistent blending can lead to uneven coloration. Use a clean stick to stir the mixture for at least two minutes. Aim for a uniform distribution of color. Experiment with different pigment ratios, but remember, too much pigment can affect the epoxy’s curing process. Reports indicate that the ideal range is 5-10% pigment by weight of the resin.

When it comes to application, use a trowel or brush for precise coverage. Pay attention to surface preparation; a clean substrate is essential for good adhesion. If the surface is rough, consider light sanding. While working, be aware of air bubbles trapped within the epoxy. They can detract from the finish. A heat gun or torch can help eliminate these bubbles but proceed with caution. Rushing through any step may lead to regrets later on in the project.