In the ever-evolving world of DIY projects and industrial applications, mastering the art of using Epoxy Resin Pigment Powder has become essential for both amateur enthusiasts and seasoned professionals. According to a recent market analysis by ResearchAndMarkets, the global epoxy resin market is expected to reach approximately $12 billion by 2027, with a significant portion attributed to the innovative use of pigments in various applications. This growth highlights not only the popularity of epoxy resin but also the increasing demand for aesthetic quality and vibrancy that pigments can provide.

Experts in the field often emphasize the critical role that Epoxy Resin Pigment Powder plays in achieving desired results. Dr. Emily Thompson, a noted researcher in polymer materials, states, “Using the right pigment powder is key to not only enhancing the beauty of the epoxy but also ensuring long-lasting durability and performance.” Her insights underline the necessity for users to fully understand the characteristics of various pigment powders, including their mixing ratios and compatibility with different epoxy formulations. By adhering to expert guidelines and best practices, both hobbyists and professionals can elevate their projects, transforming basic epoxy applications into stunning visual masterpieces.

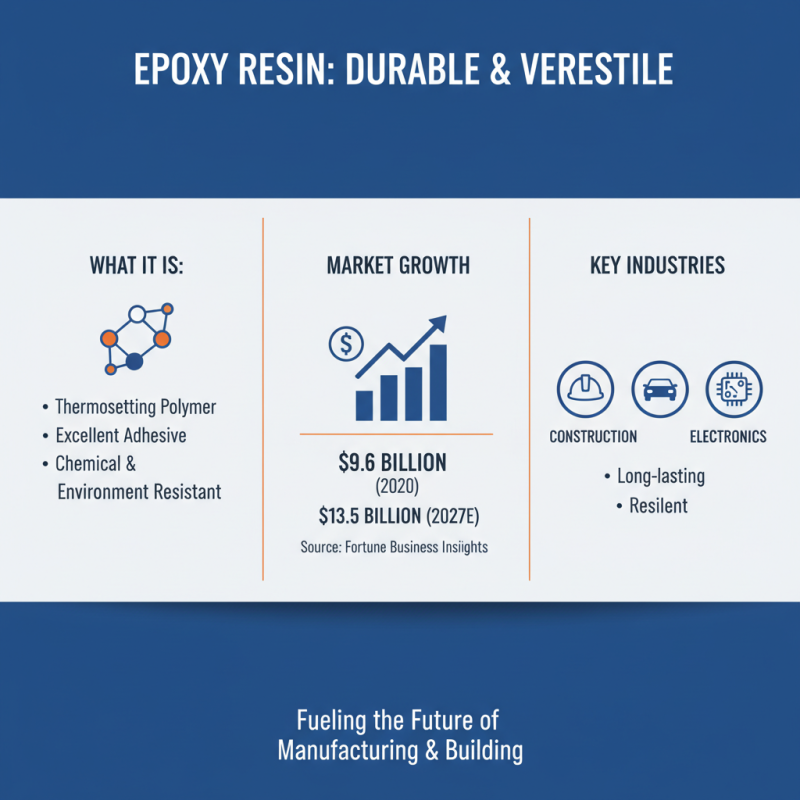

Epoxy resin has become a popular choice in various industries for its durability and versatility. As a thermosetting polymer, it is known for its excellent adhesive properties and resistance to chemicals and environmental factors. The global epoxy resin market was valued at approximately $9.6 billion in 2020 and is projected to reach around $13.5 billion by 2027, according to a report by Fortune Business Insights. This growth is fueled by epoxy's widespread use in construction, automotive, and electronics, where its long-lasting and resilient nature is essential.

Pigment powders specifically designed for epoxy resin applications enhance the aesthetic appeal of the final product. These powders are finely milled materials that can be mixed with epoxy to achieve a range of colors and effects, allowing creators to customize their projects. According to a study published by Market Research Future, the demand for colored epoxy will rise significantly, with a projected CAGR of over 5% from 2021 to 2026. Understanding the correct ratio of pigment powder to resin is crucial for achieving a vibrant finish, as excessive pigment can compromise the resin's properties. Furthermore, using high-quality pigment powders ensures better lightfastness and stability, which are critical for outdoor applications where color longevity is a priority.

When embarking on a project that involves epoxy resin, selecting the right pigment powder can significantly impact both aesthetics and functional properties. The color you choose not only influences the visual appeal but can also affect the resin's curing process and final performance. Industry reports have shown that color selection can alter light transmission and temperature stability within the cured resin, making it essential to consider various pigment characteristics before making a choice. For instance, metallic pigments may enhance UV resistance, while vibrant colors can provide better durability against fading.

Tip 1: When selecting pigments, always check for compatibility with your specific type of epoxy resin. Some pigments may interfere with the curing process, leading to suboptimal results. A study indicated that using incompatible pigments could reduce tensile strength by up to 30%, underscoring the need for thorough research on pigment-resin compatibility.

Tip 2: Pay attention to the concentration of the pigment powder. A higher concentration may yield a more vivid color, but it could also cause issues with curing. A reliable benchmark is to start with a concentration of about 5-10% and adjust based on the desired color intensity and application requirements.

Tip 3: Consider the application method, as some pigments perform better with certain techniques. For layered applications, translucent pigments can produce stunning depth, while opaque pigments may suit solid color casts. An industry review noted that the method of application could influence color perception by as much as 40%, emphasizing the importance of matching pigment type with technique.

| Tip Number | Tip | Description |

|---|---|---|

| 1 | Choose Quality Pigments | Opt for high-quality epoxy pigments to ensure vibrant colors and longevity. |

| 2 | Understand Pigment Concentration | Use the right concentration for desired opacity and color intensity. |

| 3 | Test Small Samples | Always test your pigments in small batches before full-scale mixing. |

| 4 | Mix Properly | Ensure thorough mixing to avoid streaks or uneven color. |

| 5 | Use Compatible Resins | Make sure your resin and pigment are chemically compatible. |

| 6 | Consider Lightfastness | Select pigments that resist fading when exposed to light. |

| 7 | Mix Gradients | Create beautiful ombre effects by gradually mixing pigments. |

| 8 | Store Properly | Keep pigments in air-tight containers away from light to maintain quality. |

| 9 | Use Clear Resin for Best Results | Clear resin helps showcase the true vibrancy of the pigments. |

| 10 | Follow Manufacturer Instructions | Always adhere to guidelines for the best performance and safety. |

Mixing epoxy resin pigment powder properly is crucial for achieving optimal color consistency in your projects. A recent industry report indicates that approximately 70% of challenges in epoxy applications stem from improper mixing techniques, underscoring the need for attention to this critical step. To ensure uniform distribution of pigment, it is essential to follow a structured mixing process that involves both measuring and blending. First, weigh the resin and hardener separately, adhering to the manufacturer's recommended ratios. Once combined, use a clean, flat mixing stick to gradually introduce pigment powder, allowing the resin to absorb the color evenly. This method not only ensures a consistent hue but also minimizes the formation of clumps that can compromise the finish.

In addition to the measuring techniques, the method of mixing plays a vital role as well. Mixing should be done slowly to prevent the incorporation of air bubbles, which can affect the final appearance of the cured epoxy. Industry studies highlight that mixing for at least 3-5 minutes helps achieve the best amalgamation of pigment and resin, with a significant reduction in bubble formation. To enhance precision, consider using a digital scale for exact pigment measurements. Why is this particularly important? An analysis revealed that deviations in pigment concentration can lead to color variations of up to 15%, making meticulous mixing a non-negotiable aspect for professionals seeking high-quality results in their epoxy projects.

This chart displays the relationship between different ratios of epoxy resin to pigment powder and the resulting color intensity levels. As the ratio of pigment powder increases, the color intensity improves, providing better consistency and vibrancy in your epoxy projects.

Achieving vibrant and rich pigment colors with epoxy resin requires careful consideration of material selection and mixing techniques. The first step to success is to choose high-quality epoxy resin pigment powders specifically designed for resin applications. These powders should be finely milled to ensure a smooth blend and consistent color saturation. It's crucial to experiment with different pigments, as each one can yield unique results depending on the base resin and the desired final effect.

When mixing pigment powders into epoxy resin, the amount used can significantly affect the vibrancy of the color. Start with a small quantity, gradually adding more until the desired intensity is achieved. To enhance the color payoff, consider using a white or light-colored base resin, which can make hues appear more vivid.

Additionally, mixing the pigments thoroughly is essential; insufficient blending can lead to uneven coloring and mottled finishes. For those looking to create depth in their projects, layering techniques can be employed, allowing for the gradual buildup of color intensity that adds dimension and richness to the final product.

When working with epoxy resins, it is crucial to prioritize safety to ensure a secure working environment. First and foremost, always wear appropriate personal protective equipment (PPE), including gloves, safety goggles, and a respirator mask, especially when working with epoxy resin pigment powders. These materials can release harmful fumes and potentially irritate the skin and eyes. Utilize gloves that are resistant to chemicals to prevent any skin contact, and ensure that safety goggles provide a proper seal around the eyes to avoid exposure to splashes.

Moreover, ensure that you are working in a well-ventilated area. Proper airflow helps to disperse any fumes that may be released during mixing and application. If possible, work outdoors or in a designated workshop space equipped with a ventilation system. Additionally, it is important to familiarize yourself with the safety data sheets (SDS) for the materials you are using. These documents provide valuable information on potential hazards and appropriate first-aid measures in case of accidental exposure. Practicing these safety precautions will significantly reduce the risk of accidents or health issues while working with epoxy resins.