When it comes to enhancing epoxy finishes, choosing the right pigment powder for epoxy is essential. Different powders can dramatically affect the final appearance and quality of your project. The vibrant colors and unique textures can elevate your creations to new heights. However, it’s important to understand their properties before making a decision.

Pigment powder for epoxy comes in various forms. Some powders mix well, while others can create unexpected results. This variability can lead to frustration if you're not cautious. Opting for a high-quality pigment can make all the difference in achieving a professional look. Yet, even the best pigmented powders can sometimes yield inconsistencies.

Color selection is also crucial and can be overwhelming. There are endless shades to choose from, and it’s easy to get lost in options. Understanding how different pigments interact with epoxy can save time and effort. Remember, experimentation is key, but it may involve some trial and error. So, before diving in, consider what works best for your specific needs.

When choosing pigment powder for epoxy, understanding types and applications is crucial. There are various pigment types on the market. The two most common are liquid and powder pigments. Liquid pigments often offer vibrant color and ease of mixing. Powder pigments, on the other hand, provide depth and opacity. According to recent industry reports, around 70% of artisans prefer powder for its versatility.

Applications vary widely. Artists use epoxy resin for crafting jewelry or art pieces. Builders and DIY enthusiasts often choose epoxy for flooring and coatings. The right pigment powder can greatly affect the final appearance. Experts indicate that adding too much pigment may affect curing times. Balancing color and composition is key. Colors can also fade if exposed to UV light for extended periods. Research shows that 40% of users report issues with color stability over time.

Some powders perform poorly in certain conditions. Not all pigments mix well with every resin type. This inconsistency can lead to unexpected results. Many find themselves experimenting. It’s a process that requires patience and tweaking. Observing how different pigments behave can be enlightening. There’s always something new to learn in the world of epoxy and pigments.

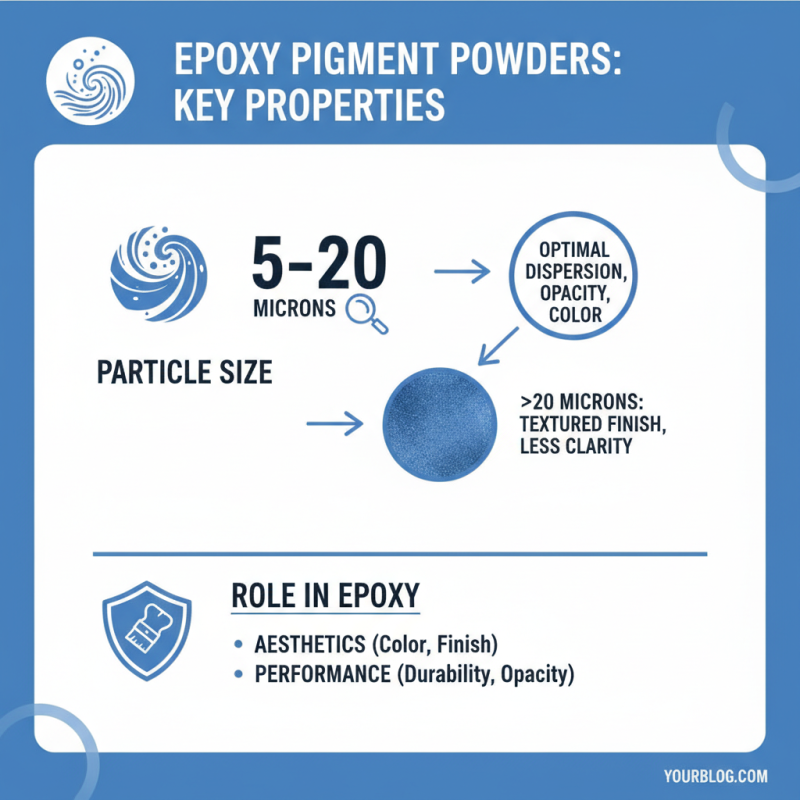

When choosing pigment powders for epoxy coatings, understanding key properties is essential. Pigment powders play a crucial role in the aesthetics and performance of epoxy resins. The particle size, for example, can significantly influence the final product's opacity and color vibrancy. The ideal particle size for optimal dispersion typically ranges from 5 to 20 microns. Larger particles may provide a more textured finish but could compromise the clarity.

Color saturation is another important aspect. High-quality powders often exhibit better tinting strength, allowing for vibrant hues with less quantity. Reports suggest that specific pigments can achieve up to 90% color retention after curing. However, it’s crucial to navigate the balance between saturation and transparency. Some mixtures may lead to unexpected dullness or uneven finishes, prompting further adjustments.

Additionally, the stability of pigment powders is a key consideration. Factors such as lightfastness and heat resistance vary widely among different pigments. For instance, organic pigments might fade over prolonged exposure to UV light. This can be detrimental for outdoor applications. It could require users to reflect on their specific needs and consider testing different formulations before settling on a final choice. Understanding these properties is vital for achieving desirable results in epoxy applications.

When considering pigments for epoxy use, a choice between natural and synthetic options can be crucial. Natural pigments derive from plants and minerals. They offer a rich, earthy palette. However, their color consistency and stability can vary significantly. For instance, some natural pigments fade under UV light. Users may find themselves disappointed with the longevity of their results.

On the other hand, synthetic pigments are engineered for stability and vibrancy. They provide a wide range of colors and ensure uniformity in application. Synthetic options resist fading and blend seamlessly. However, they often lack the warmth that comes from natural materials. Additionally, ethical considerations arise regarding environmental impact. Choosing sustainably sourced synthetic pigments should not be overlooked.

Both types have unique merits and drawbacks. It’s essential to experiment and observe the results. This trial and error process helps users understand what works best in their specific projects. A thoughtful approach can lead to surprising discoveries in the world of epoxy art.

When working with epoxy resin, understanding pigment load ratios is essential. The right amount of pigment can enhance color vibrancy without compromising the resin’s performance. Generally, a load of 5% to 10% pigment by weight is recommended for most applications. This ratio provides rich color while maintaining clarity.

However, achieving the perfect balance can be a bit tricky. Too much pigment can lead to issues such as cloudiness or curing problems. Also, not all pigments are created equal. Some might require more or less to achieve desired results. Experimentation is often necessary. It’s important to test small batches before committing to larger projects.

Consider starting at the lower end of the recommended range. Assess the opacity and hue. Gradually increase the pigment until you reach the desired effect. This approach allows flexibility. Remember, each epoxy and pigment combination can behave differently. Accurate measurements and patience are key. Embrace the possibility of trial and error in your creative process.

Innovations in pigment powders for epoxy applications are rapidly evolving. Artists and manufacturers alike are demanding more from their materials. Color vibrancy and stability are crucial. New formulations now offer enhanced UV resistance and better adhesion. This is essential for outdoor projects. In addition, some powders now come with eco-friendly properties. It’s a step towards sustainability that cannot be overlooked.

Another trend is the increasing popularity of metallic and pearlescent pigments. These offer depth and eye-catching effects. They are frequently used in art and design projects. However, achieving consistency with these powders can be challenging. Users often face issues with mixing and settling. This is an area where improvements are needed.

Finally, advancements in technology are shaping how we create and use these pigments. 3D printing and light-induced curing processes are becoming more common. Yet, the cost of new technologies can be high. This limits accessibility for smaller businesses and artists. It’s a balance between innovation and practicality that the industry must navigate.